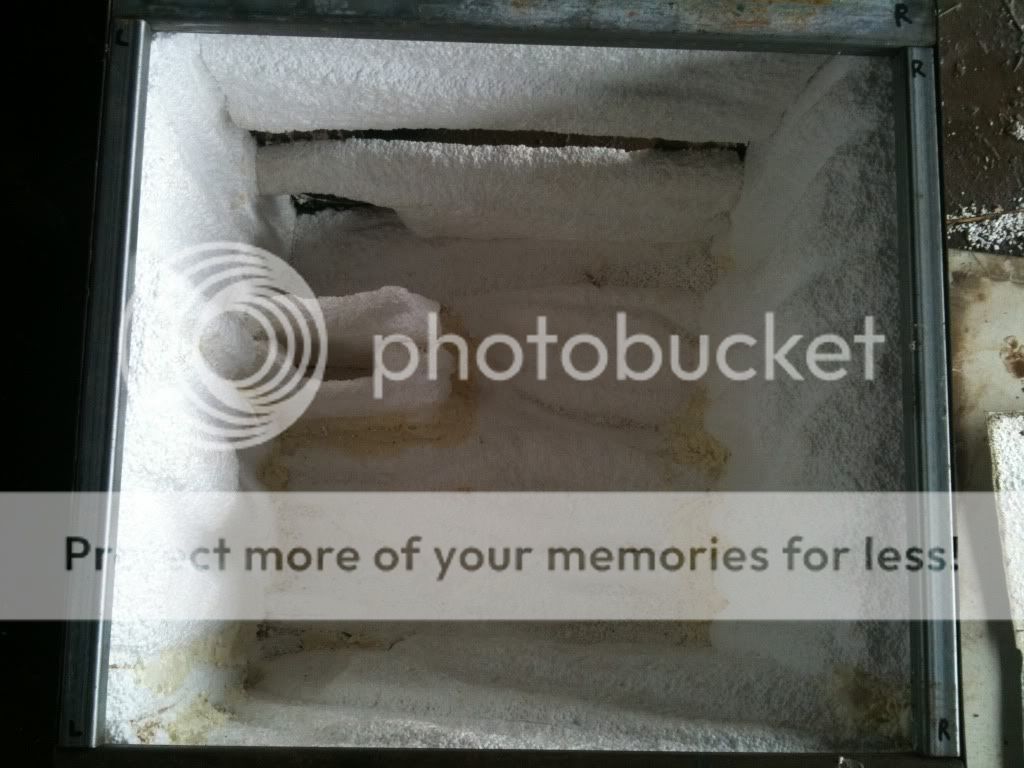

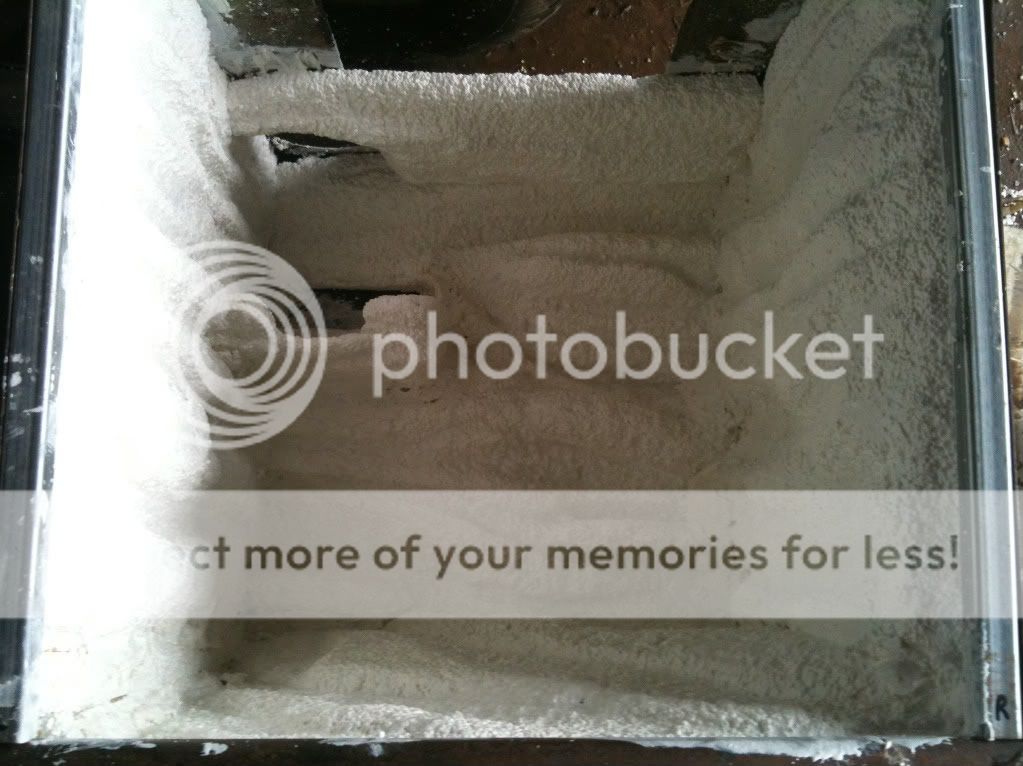

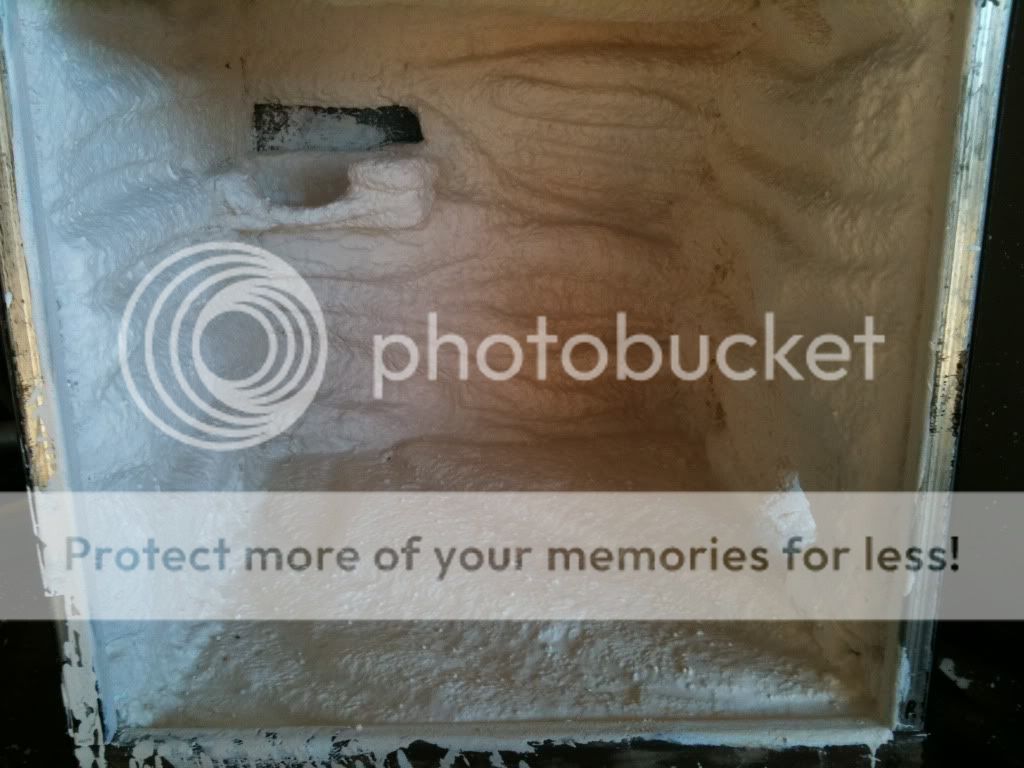

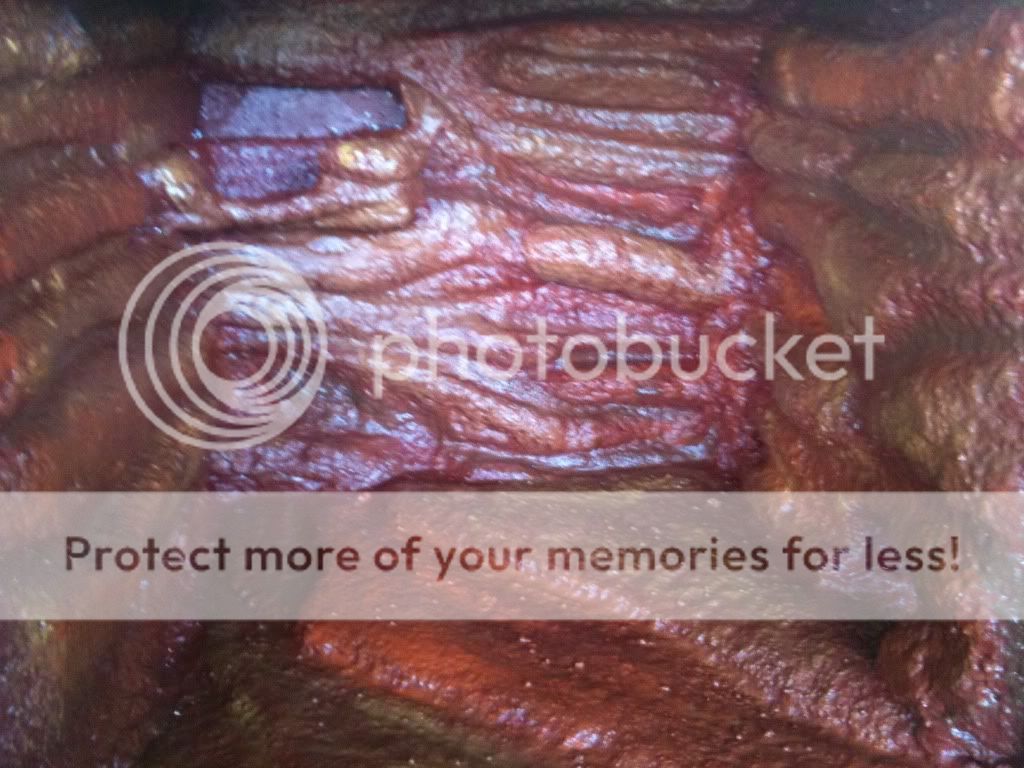

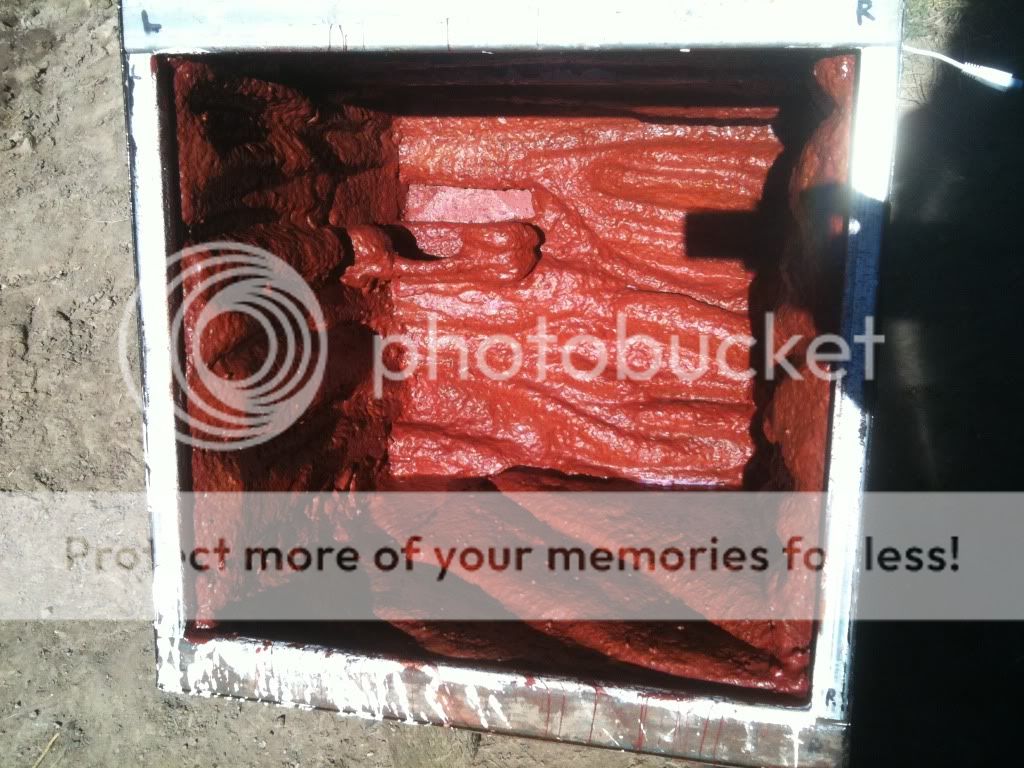

Hey i've been making a new enclosure for my jungle hatchy and had a few questions. does anyone have any ideas to fill large holes in my background? i've tried expanda foam but its proving difficult to shape and cut away in these spots. Secondly, is it possible to speed up the drying of grout easily without resulting in cracking or other deformities? and thirdly, is it best to apply sealant before or after painting and detailing the background? any input would be helpful.

Cheers Tim

Cheers Tim